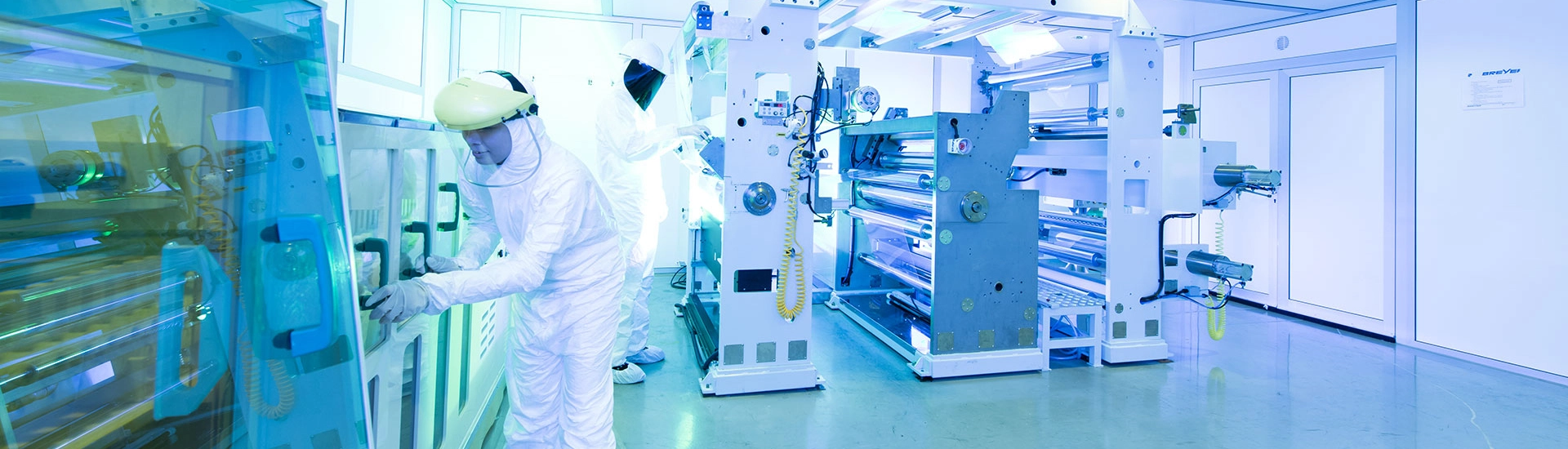

BREYER flat film extrusion line

Technical data of the equipment

| Material: | PC, PMMA, PET-A, -C, PET-G, PLA, PS, COC, PES, ETFE, FEP |

Roll width: | 1600 mm |

Line speed: | 40m/min |

| Extruder: | BREYER high performance extruder ø 75mm x 36D, rpm up to 600 1/min |

| Screws: | Standard venting screw as well as different barrier-type screws |

| Coextruder: | Two BREYER coextruders ø 35x36D, with venting, rpm up to 164 1/min, venting screw, melt pump with 4,5 cm³/U |

| Vacuum pump: | Dry running vacuum pump with filter, 60 mbar, 140 m³/h |

Flat sheet dies: |

|

| Calender: | Horizontal calender with three solid steel rolls (350/450/450 mm, surface mirror polished), 3. roll slewable, servohydraulic roll gap adjustment with distcance and pressure control mode |

| Additional rolls: | 1x FSR roll ø 350 mm, width 1600 mm, chromed surface, mirror-polished 1x matt roll ø 450 mm, width 1600 mm, chromed surface, matt Ra=2 µm 1x rubberized roll, ø 350 mm, width 1600 mm |

| Thickness: measurement: | Make Thermofischer with Krypton source Kr 85 and Strontium source Sr 95 |

| Haul-off: | Haul-off with 2 rubberized rolls, width 1600 mm, ø 260 mm, straight run-through resp. s-shaped clinch |

| Masking: | protective film masking equipment with 4 unwinding stations, controlled tractive force magnet powder brakes, 3” winding shafts |

| Waste strip: | waste strip feature with 2 driven circular knives, waste strip winder |

| Winder: | 2-station turret winder with reverse winder and 30 m storage, winding width max. 1400 mm, winding ø max. 800 mm, 6“ clamping shafts, winding speed max. 60 m/min |

Additional equipment: | cross cut saw for cutting thick film and sheets |