INNOVATIONS FOR BETTER SOLUTIONS

Welcome to K2022 at Düsseldorf!

We look forward to seeing you at our stand in Hall 16/D38 from 19–26. October 2022.

We will present innovative solutions to you - individual, digital, sustainable.

INDIVIDUAL

BREYER customers are innovative and creative.

With BREYER systems, you are able to produce the products of the future in the automotive, architecture, electronics, leisure, medicine, energy (lithium-ion batteries, solar panels), and packaging sectors.

In the automotive sector, for example, plastics that originate from extruded film or sheet stand behind the technology of a breathtaking design, fascinating interior lighting, and intuitively operable functional elements.

Those who stand still in the market will quickly fall behind.

For our customers, it is especially important to continuously offer new solutions that promise success and being in the lead in the market. Upon request, BREYER will provide you with custom-tailored solutions for your future success.

Get inspired by this diversity at our trade show booth!

DIGITAL

The future is digital – discover the new BREYER e-Portal with us.

At the trade show, we present to you the new BREYER e-Portal. Learn what maintenance, spare part sourcing, and system transparency will look like in the future.

Discuss your requirements for the digital future on the way toward the “learning machine” with us. The BREYER e-Portal as a hub for your extrusion processes gives you a glimpse of the world of tomorrow!

ENERGY SOLUTIONS

Encapsulation films for photovoltaic modules

Extrusion line for the encapsulation of PV modules – complete line turn-key.

The BREYER CellProtect extrusion system enables the production of low-shrink EVA and POE films at high production speeds.

Another advantage – no energy-consuming post-tempering and no intermediate film make the production economical and energy-saving.

Benefit from our many years of know-how and the opportunity to receive a TÜV-tested recipe in addition to the system.

Breyer offers you the complete line from the complex direct dosing, extruder, process unit for low-shrink films to the labeling system for the coils ready for sale.

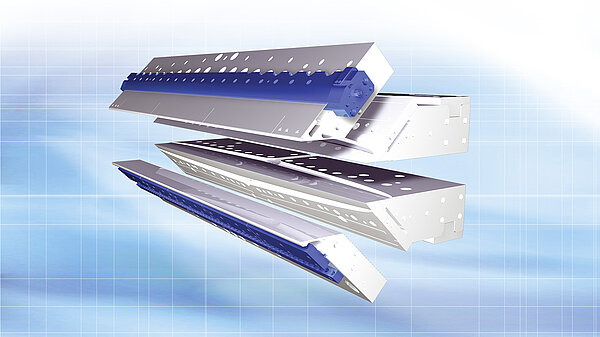

Flat sheet dies for film and sheet production

Precision tools for extraordinary products

Create and design new products with extraordinary properties with the BREYER multi-layer technology. Our single and multi-channel dies can be combined with different feedblock systems. You have the choice. And with it many possibilities.

SUSTAINABLE

Responsibility for our resources.

BREYER presents the most diversified and varied tube extrusion ever. Produce 5-, 6-, and 7-layered tubes with the highest performance.

Greener:

Due to the special BREYER technology, the use of recycled materials at a high level is possible – as are barrier tubes with up to 86% recyclables.

The advantageous alternative for ABL laminate tubes: produce fully recyclable ultra-high barrier tubes through coextrusion. BREYER offers unique possibilities to produce packaging in an energy-saving, efficient, and sustainable way. At K2019, we will present the options to you with our BREYER TopLine 7-layer tube line, for example.

Plastics products also become sustainable!

Innovative plastics made of sustainable materials and recycled materials from internal or external recycling can be processed into high-quality products on BREYER systems. Thanks to BREYER’s multi-layer extrusion, tubes can even be made of natural resources, such as wood or sugar cane.

Convince yourself of the possibilities!